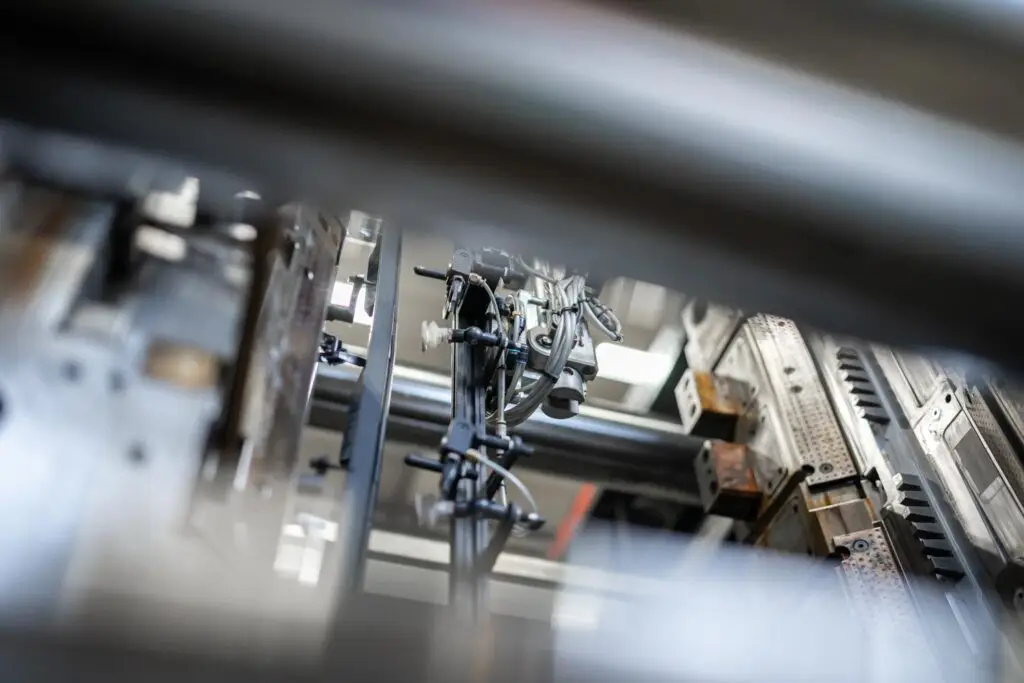

Here you will find information about how we work with injection molding to meet the standards of high demanding industries. Our technology and machinery make it possible to manufacture both simple and advanced parts.

Injection molding is the core of our business. We manufacture plastic parts for the automotive, electrical, healthcare, construction and engineering industries, among others.

By choosing the right material and adapt machines and processes to each product, we can meet high demands. We offer various co-molding techniques such as plastic to plastic, plastic to metal and plastic to rubber.

A high degree of automation and careful quality control give us an efficient production with consistent and high quality.

Would you like to know how we ensure quality, environmental consideration and delivery reliability in every assignment? Read more about our working methods and our certifications.

Whether it’s small details or technically advanced components, we our adapt production to meet your needs. Our modern machinery and high degree of automation make it possible to produce with both precision and efficiency.

We have extensive experience in co-molding and are happy to help with material selection and design. Combinations such as plastic and metal or plastic and rubber are a natural part of our offering.

Through close cooperation and good communication, we create solutions that work in practice. With control at every stage, we deliver products that meet your standards.

We handle most things related to injection molding and we are happy to discuss how we can help your company. Contact David Alkemark and he will tell you more.