Here you will find information about how we develop tools for injection molding – a crucial part in producing the right plastic part with the right quality.

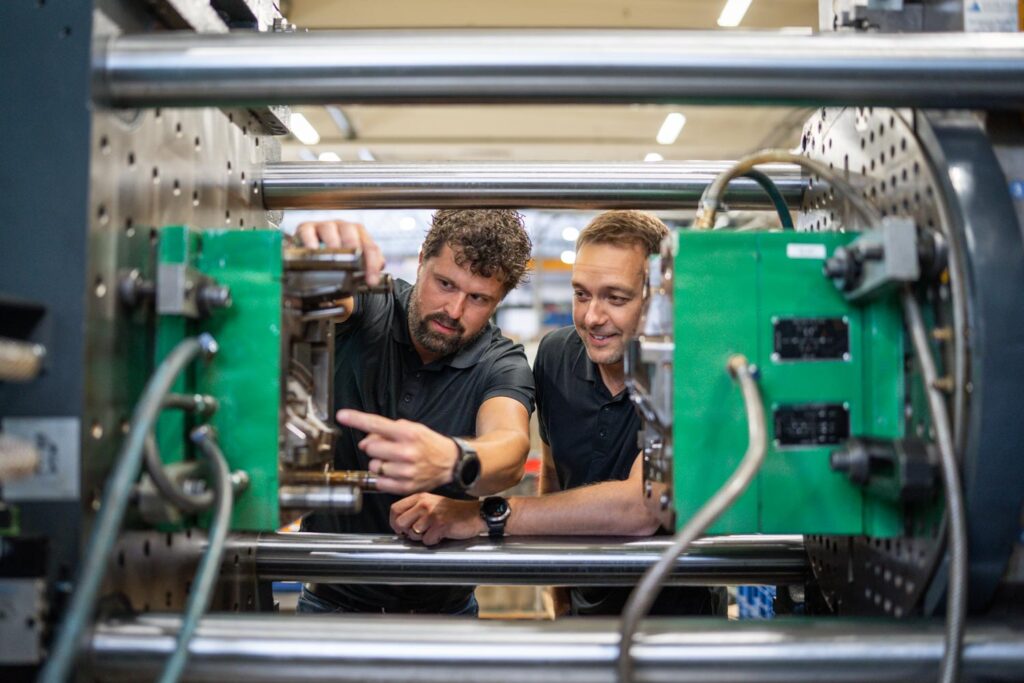

A good tool is the basis for a functioning injection molding process. We manage the entire process, from tool design to finished delivery, in close dialogue with both the customer and the toolmaker.

The tools are adapted to the shape, material and life requirements of the part. For smaller series or prototypes, aluminum is often used, while steel inserts and hardened tools are used for larger volumes. We ensure that the tools receive the correct cooling, flows and geometry right from the start to avoid problems in production.

Do you have an idea or a project you would like to discuss? Contact us and together we will find a solution that suits your company.

We are involved all the way, from the first sketch to the finished plastic part. The earlier we get involved, the greater the opportunities to save both time and money through smart material choices and the right design.

In many cases, metal can be replaced with plastic, which reduces both cost and impact on the environment. We offer tool construction through partners in Sweden and Asia, depending on what suits best. Prototypes are developed in close dialogue with the customer to ensure function and form.

When production starts, we can show what we stand for – high quality, stable delivery and full control. If necessary, we also ensure that the product is kept in stock.

We are happy to discuss with you how we go about developing injection molding tools. Contact David Alkemark and he will tell you more.